CAE tool

This tool contains various analysis techniques based on our years of know-how. It enables early detection of issues in design and quality as well as timely feedback through various simulations, supporting customers in production realization which fulfills all their needs.

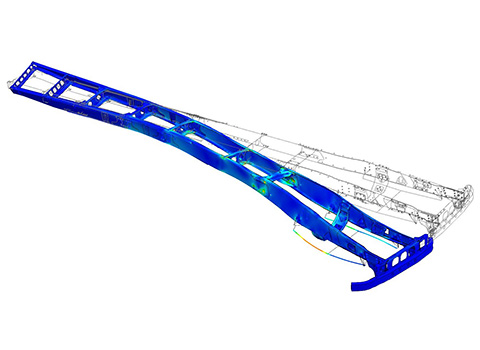

Structural analysis

/p>

/p>

We offer evaluation of required performance of a product according to its intended use, through structural analysis of the product.

For any issue or challenge revealed in the analysis, we propose the best product shape based on our know-how.

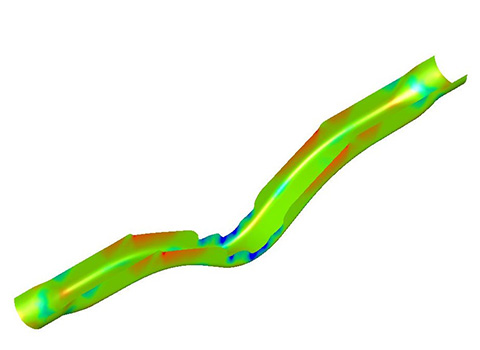

Press molding simulation

At the early stage of mold investigation, we predict possible problems which might arise during press molding and provide feedback to mold designing, contributing to a shorter production lead time.

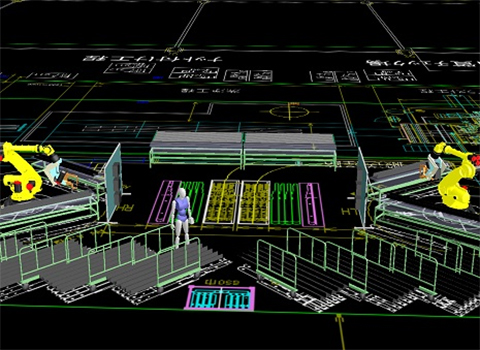

Assembling production line simulation

By creating a virtual assembly line on a computer to predict possible load and performance of line workers, we determine the best line configuration and facility specifications to offer to our customers.

Super high tensile strength steel processing

Super high tensile strength steel can contribute to weight and cost saving by being used instead of other materials. On the other hand, it has a bottleneck property that lowers its stretch as its tensile strength is improved; therefore, it is difficult to mold this material as it is prone to produce cracks during press molding.

We have been leading the industry in self-manufacturing of press working of super high tensile strength steel plates (3 mm and above in thickness). For example, by changing the material of a FUP (front under run protector) from conventional aluminum to super high tensile strength steel, we could save more than 40% in cost while maintaining the equivalent mass to that of aluminum FUP.